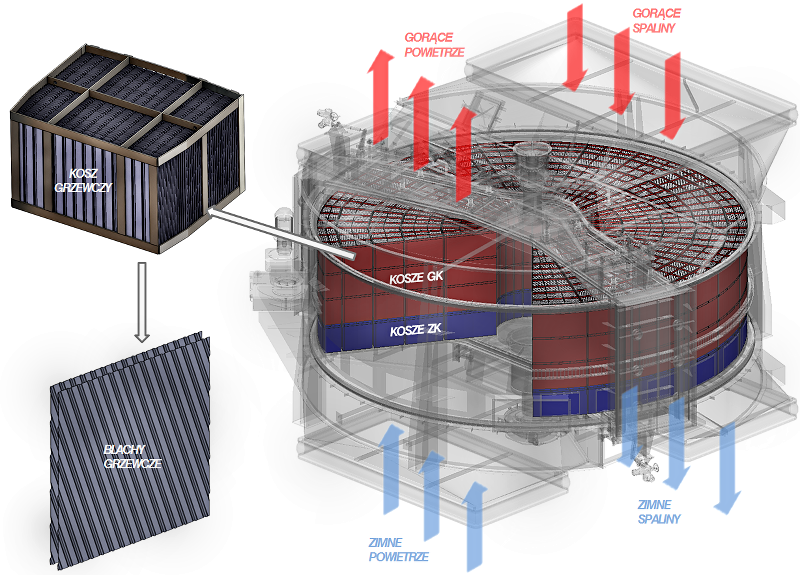

Heating baskets

During each rotation of the rotor, the exhaust stream hits thousands of square meters of heating surface in the form of closely fitting, specially profiled sheets filling the rotor, packed into packages called heating baskets. Heating baskets collect thermal energy from exhaust gases and transfer it to the air involved in the combustion process. All this takes place at rotor revolutions of 1÷3 per minute.

The LUVO rotor has one layer of cold end heating baskets and 1 to 3 layers of hot end heating baskets. Cold end heating baskets operate at a lower temperature, which is why they differ from hot end heating baskets, sometimes in terms of material and always in the filling profile.

MATERIAL

Depending on the chemical composition of the exhaust gases, we use different types of steel to fill the baskets:

DC01

This steel is most often used to fill hot end baskets. Its advantage is susceptibility to plastic processing and low price.

Corten

This steel, called "rain steel", is characterized by increased resistance to corrosion, i.e. under the influence of moisture, a protective coating resembling rust is formed on its surface. For this reason, it is mainly used as a filling for cold end baskets.

Enamelled steel

It is steel covered with a thin layer of enamel with low surface adhesion and high resistance to acids and moisture contained in exhaust gases and, which is why we use it for the most aggressive exhaust gases.

Duplex

This steel is characterized by high mechanical properties and the highest resistance to corrosion and erosion. Its disadvantage is the high price and the possibility of using it at temperatures of 300°C.

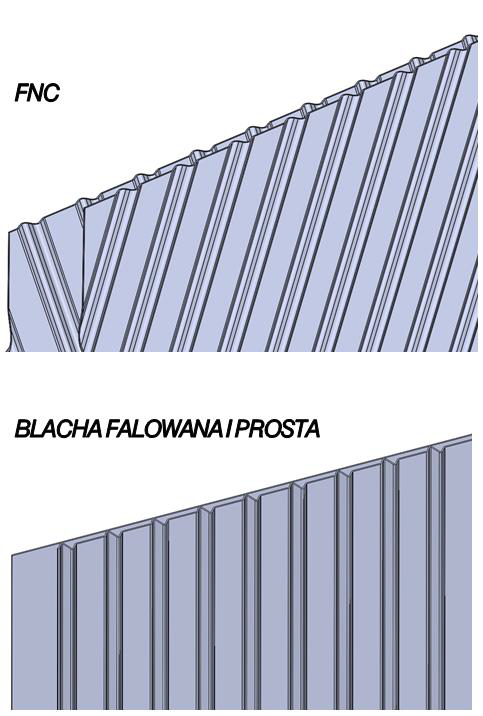

FILLING PROFILE

We use sheets of various profiles to fill the heating baskets to achieve optimal heat exchange.

We most often use the FNC profile in hot end heating baskets and the NF profile (combination of corrugated and straight sheetl) in cold end heating baskets. The FNC profile has the best heat transfer but higher flow resistance, while the NF profile has worse heat transfer but lower flow resistance and greater resistance to dust deposition.