Control systems of radial leaves position

Control systems of radial leaves position

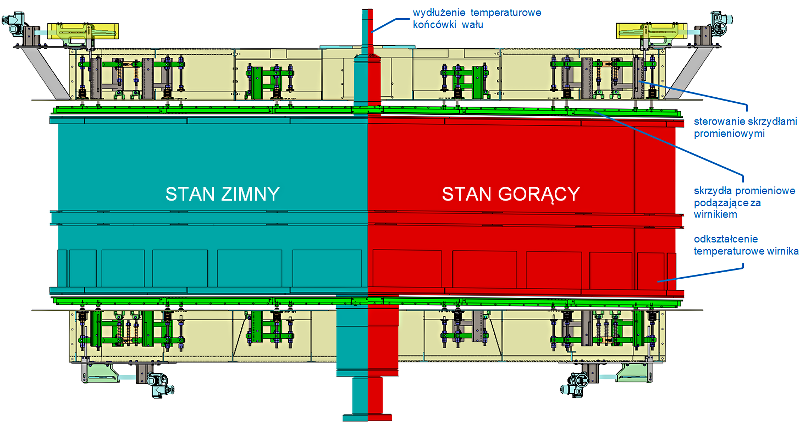

The rotating rotor undergoes thermal deformations. In order to minimize the gap between the seals and the casing plates, radial leaves are used, the position of which can be adjusted manually or automatically.

The ways to control the position of radial wings:

Two-state system

- the wings are in the "cold" or "hot" state. After the flue gas reaches the set temperature, the wings are re-adjusted to the "hot" state and after the boiler is turned off, the wings are returned to the "cold" state.

System with mechanical strain measurement (following system)

There is a pusher mounted on the rotor, which changes its position as the rotor deforms by another 2 mm. While the rotor is deforming, the pusher acts on the pulse receiver lever, as a result of which the signal goes to the system controlling the position of the wings. In this arrangement, the wings follow the deforming rotor, maintaining the set gap with a tolerance of +/- 1 mm.

System with proximity sensors (the most advanced tracking system).

In this case, continuous measurement of the position of the rotor's peripheral ring is made using proximity sensors mounted on the LUVO housing, thanks to which the gap is maintained with a tolerance of +/- 0.5 mm.