About the leakage

About the leakage

The main goal of the LUVO modernization is to reduce air leakage into flue gas (modernization of seals) and improve heat transfer (modernization of heating baskets), which reduces the power consumption of fans, increases the efficiency of dust removal in the electrostatic precipitator and reduces the outlet loss from the boiler.

A rotor diameter of 4 - 16 m and a temperature difference between the cold and hot ends of up to ~400°C cause rotor deformations reaching up to several centimeters around the circumference. These deformations change as the boiler load changes. Moreover, there is a pressure difference between the air (overpressure) and the flue gas (negative pressure), which is the main cause of air leakage into the flue gas. As we know, there is no technology that can completely eliminate leakage, but we offer methods that radically reduce it.

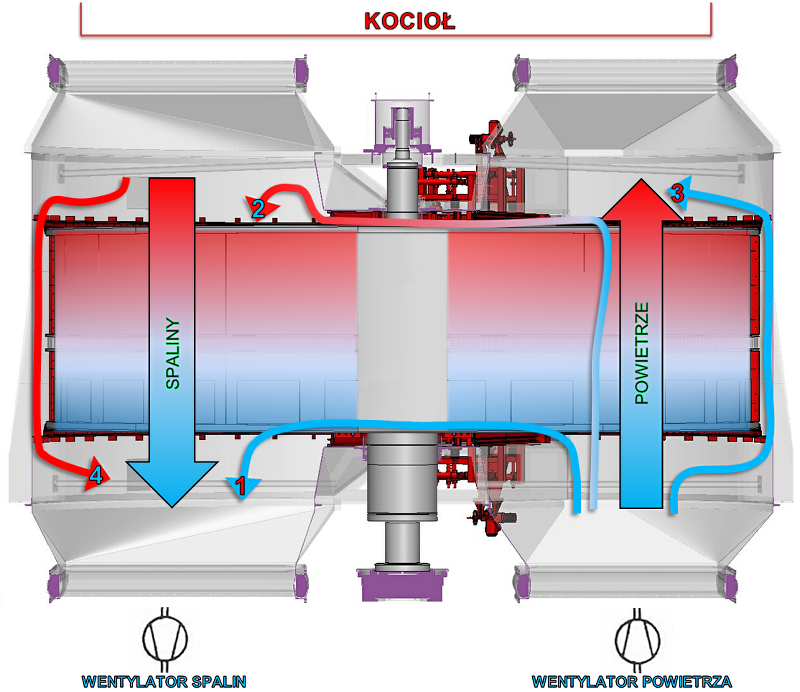

The figure shows areas of undesirable air flow into flue gas, which reduces the flue gas temperature and increases the flue gas flow and oxygen content in the flue gas.

1. Ambient air is drawn into the flue gas duct through the gaps between the radial seals and the wings.

2. The heated air, after passing through the rotor, is sucked into the intake flue gas duct through the gaps between the radial seals and the wings.

3. The air bypasses the rotor around the cold air duct and enters the space between the rotor and the peripheral seals. Some of the air bypasses the peripheral seals at the upper end and goes directly to the hot air duct, and some of it is sucked into the flue gas duct through the gaps between the axial wings and the rotor.

4. The flue gas bypass the rotor around the hot end flue gas duct and enter the space between the rotor and the peripheral seals.